Double Offset vs Triple Offset Butterfly Valves: 8 Key Differences

Choosing the right butterfly valve for your application is crucial for ensuring system efficiency, reliability, and longevity. Among the options available, double offset and triple offset butterfly valves are popular choices in industrial settings. Understanding the difference between double offset and triple offset butterfly valves can help you make an informed decision tailored to your operational needs. This article explores the fundamental characteristics of these valves and highlights eight key differences to guide your selection process.

What Is a Double Offset Butterfly Valve?

A double offset butterfly valve features two distinct offsets that improve valve operation and sealing compared to concentric or single offset designs. The first offset moves the valve shaft away from the centerline of the valve body, minimizing friction between the disc and seat during operation. The second offset shifts the shaft away from the pipe bore centerline, allowing the disc to move more freely and reducing wear on the sealing surfaces. This design reduces sealing surface friction, extends valve life, and improves flow control accuracy. Double offset butterfly valves typically use soft seats to achieve a tight seal, making them suitable for moderate temperature and pressure applications.

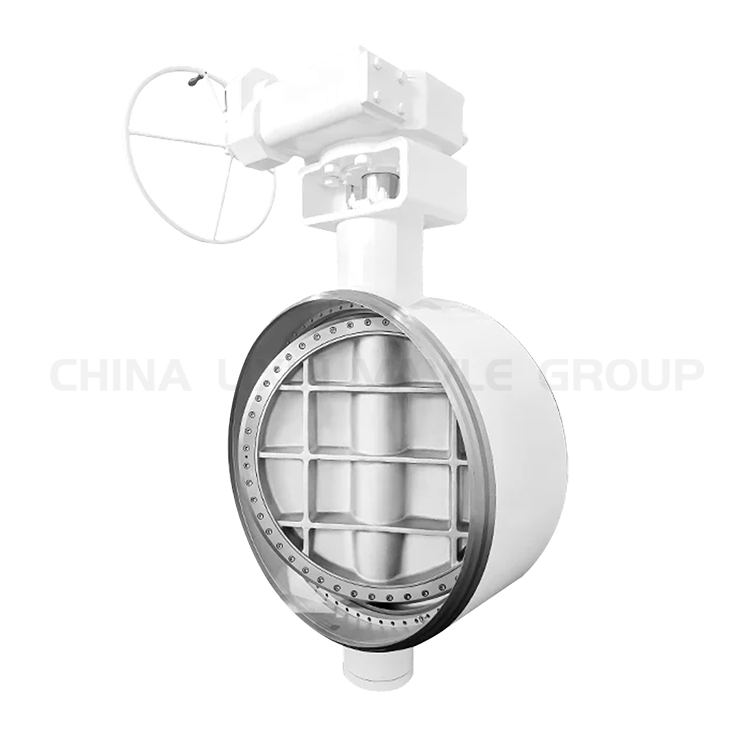

What Is a Triple Offset Butterfly Valve?

Triple offset butterfly valves advance the design further by incorporating a third offset in addition to the first two. This third offset involves the geometry of the sealing surfaces, which are shaped into a cone. The sealing surfaces engage only at the final degree of valve closure, resulting in a metal-to-metal, frictionless seal. This design eliminates rubbing between the disc and seat during operation, substantially increasing durability and reliability. Triple offset valves are ideal for high-temperature, high-pressure, and demanding industrial applications where tight shutoff and long service life are critical.

8 Key Differences Between Double and Triple Offset Butterfly Valves

| Key Difference | Double Offset Butterfly Valve | Triple Offset Butterfly Valve |

|---|---|---|

| Eccentricity Number | Two offsets: shaft is off-center from valve body and pipe bore | Three offsets: adds a conical sealing surface for zero rubbing |

| Structural Design | Soft-seated with dual offset geometry; reduces friction but some contact still occurs | Metal-to-metal, cone-angle sealing that avoids contact until full closure |

| Sealing Form | Elastomeric or soft seat | Metal-to-metal seat |

| Sealing Performance | Good, but may degrade under harsh or cyclic conditions | Excellent, bubble-tight shutoff even under extreme service conditions |

| Temperature & Pressure Limits | Suitable for moderate temperature and pressure | Ideal for high-temperature and high-pressure environments |

| Industry Applications | HVAC, water treatment, light chemical processing | Oil & gas, power generation, petrochemicals, and other critical services |

| Cost | Lower initial cost due to simpler design and materials | Higher cost, but better long-term value due to reduced wear and maintenance |

| Automation Capability | Can be automated but may need higher torque and more maintenance | Highly compatible with automation systems due to frictionless operation and lower torque requirements |

Eccentricity Number

Double offset valves have two offset axes: one shifting the shaft from the valve centerline and another offsetting the shaft from the pipe bore centerline. Triple offset valves add a third offset related to the conical sealing surfaces, providing superior sealing and reduced friction.

Structural Design

The double offset valve design uses two axes to reduce friction and wear between disc and seat, relying on soft seats for sealing. Triple offset valves employ a right-angled conical sealing surface that enables a cam-like action, preventing contact until full closure, which significantly extends valve lifespan.

Sealing Form

Double offset butterfly valves usually feature elastomeric or soft seats that compress to create a seal, prone to wear over time. In contrast, triple offset butterfly valves utilize metal-to-metal sealing surfaces, enabling more durable and reliable sealing performance.

Sealing Performance

Due to soft seats, double offset valves may experience leakage or seat degradation under harsh conditions or extended cycling. Triple offset valves deliver a bubble-tight shutoff with negligible leakage, suitable for severe service applications.

Applicable Temperature and Pressure

Double offset valves are typically suited for moderate temperature and pressure ranges. The triple offset design can withstand higher temperatures and pressures, making it appropriate for applications with extreme conditions.

Applicable Industry Applications

Double offset valves are widely used in water treatment, HVAC, and chemical processes where conditions are less demanding. Triple offset valves serve in oil and gas, power generation, and other industries requiring high durability and precision under severe operating conditions.

Cost

Double offset butterfly valves generally have a lower upfront cost due to simpler manufacturing and materials. Triple offset valves require specialized machining and premium materials, reflecting in a higher price but offering long-term savings through reduced maintenance.

Automation Capability

The reduced operating torque and frictionless sealing of triple offset valves make them highly compatible with automated actuators and control systems. While double offset valves can be automated, they may require higher torque and more frequent maintenance.

How to Choose the Right Valve?

Selecting between double offset and triple offset butterfly valves depends on several factors: operating temperature, pressure, fluid cleanliness, required shutoff tightness, and budget. For applications with moderate conditions and budget constraints, double offset valves can provide reliable service. For critical processes demanding high sealing integrity, extended service life, and compatibility with automation, triple offset valves are the better choice.

Find the Best Triple Offset Butterfly Valve at Cnlxv

At Cnlxv, you can find a comprehensive range of triple offset butterfly valves engineered for durability and performance across demanding industrial applications. Our valves are designed to meet stringent quality standards and offer reliable sealing under extreme conditions. Contact us to discover how our triple offset butterfly valves can optimize your process operations.

Conclusion

Understanding the difference between double offset and triple offset butterfly valves is essential to selecting the optimal valve for your needs. While double offset valves offer cost-effective solutions for moderate conditions, triple offset valves provide superior sealing, durability, and automation capabilities for challenging environments. By carefully considering the key differences outlined in this article, you can make an informed decision that enhances system reliability and operational efficiency.

Request a Quote

Request a Quote